DIY plywood crafts and drawings for a summer residence. Plywood crafts for children. Construction and transfer of a drawing. Sawing and assembling parts. Finishing Cool things made of wood and plywood

A sheet of plywood is a multi-layer material. It consists of several glued wooden sheets. The wood used is beech, pine and birch. They have different colors and structures, so when choosing a type of wood, it is necessary to take into account the peculiarities of its processing.

The higher the quality of the material, the easier it is to work with and the higher the strength of the finished crafts.

You should start work only with dried plywood. Under-dried wood can dull or break the blade of cutting tools.

The following woodworking tools may be needed:

- jigsaw;

- drill;

- awl;

- wood burning tool;

- grinding machine.

Finished products are cleaned sandpaper, varnished or painted with multi-colored paints.

Options for crafts made from plywood

Plywood is so versatile that you can create a wide variety of things from it: decorative elements, toys, furniture, souvenirs.

Decorative frame

From plywood you can cut a regular rectangular photo frame, shaped parts with patterns that can be used to decorate the interior.

The process of making carved products involves drawing a template on a sheet of plywood, for example, with a pencil, and then cutting out the patterned elements.

Finished crafts are cleaned and covered with varnish, paint or other top coating for wooden surfaces.

Furniture for dollhouse

When creating toy furniture, preliminary design of the future craft is important. It can be drawn on paper or made completely like a real thing in miniature size.

The furniture is cut out with a jigsaw, then processed using sandpaper or a sanding machine.

You should take into account the quality of the material used, do not cover furniture for toys toxic substances and carefully treat the surface.

It is best to coat such crafts with varnish or non-toxic paint.

Burning on plywood

A sheet of plywood is an ideal material for burning out paintings, patterns and ornaments in different styles.

Using this technique, not only individual paintings are created, which are ready-made souvenirs, but also decoration elements for other crafts, for example, furniture, boxes, doors, etc.

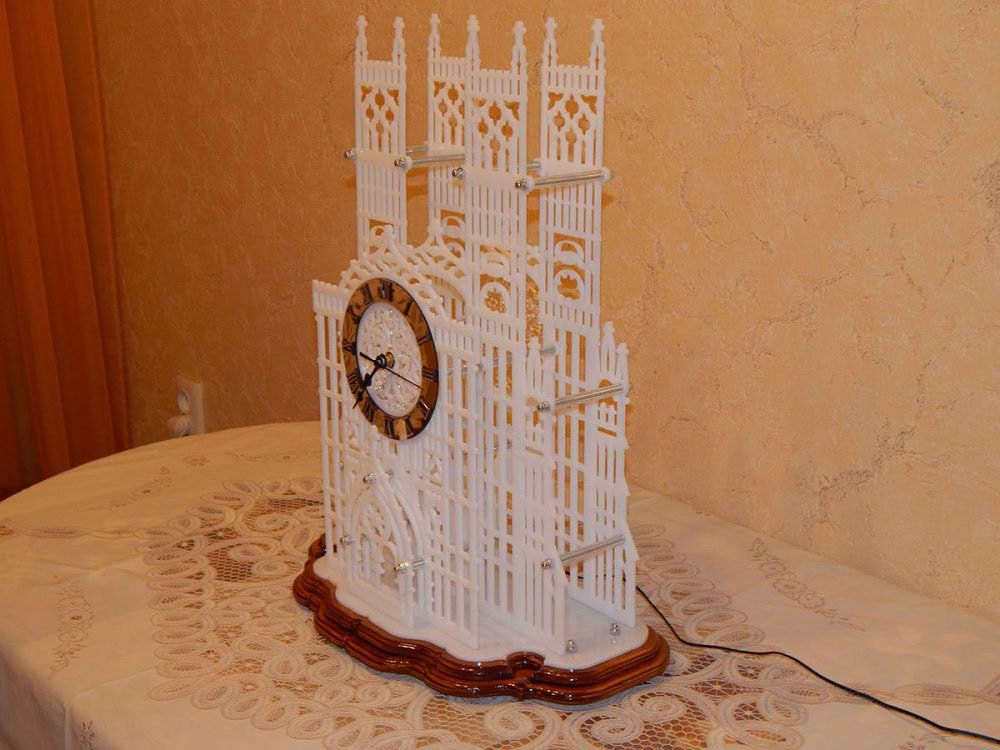

Lamps

Plywood makes beautiful and cozy lampshades that use LED lamps. Compared to conventional incandescent light bulbs, modern LEDs have no heating elements, which makes them safe to use in wooden lamps, floor lamps and chandeliers.

The light from such lamps comes in the form of patterned figures, stripes and other original shapes - here you can use not only ready-made options, but also come up with your own fancy ideas.

Wooden utensils

Such items serve as interior decoration or auxiliary items in the kitchen. For example, teapot stands, hot dishes, mugs, as well as containers for fruit, bread or eggs. One of the most popular plywood products are cutting boards. They can be made in any form and individual for each type of product - meat, fish, fruits and vegetables, etc.

Hangers for wardrobes with clothes

To create wooden hangers, you just need to draw the outlines with a pencil and cut out the finished item.

The hangers can be decorated with patterns, inscriptions, drawings according to your own taste.

Such things will become a great gift, will emphasize the individuality of the owner and will ideally suit his style and wardrobe.

It should be noted that they can only be coated with varnish, because... Coloring compounds can wear off with daily contact with fabric.

Hangers with hooks

In order to hang some things on the wall, for example, jackets or keys, you can cut a special hanger from a sheet of plywood.

A base is cut out of a single sheet in any shape, hooks are attached to it and the structure is decorated with varnish and additional carved details.

Volumetric sculptures

Products are made from several layers connected to each other with glue or inserted into each other.

These can be animal figures, silhouettes of people, and other unusual options.

Furniture for home

Plywood is used to create real furniture of all shapes and sizes. Curved furniture, such as chairs and tables, is becoming a popular option.

A sheet of plywood is bent after preliminary steaming or making small cuts in the opposite direction from the fold lines.

Plywood - universal material, allowing you to create not only crafts and toys, but also useful things for the home, household items and many others interesting products. At the same time, they are unique and give the room a special comfort and style. It is also worth noting the environmental friendliness of wooden crafts - thanks to this, they will not go out of fashion for a long time and will remain one of the most popular and classic materials for a long time.

Before you make furniture from plywood with your own hands, which can serve long time Faithfully, you should study all the physical properties of the material and the rules for its processing.

Plywood is a material that does not require any special tricks during processing. This material, used in making furniture from plywood with your own hands, has another significant advantage - low cost.

Plywood is a material that does not require any special tricks during processing

There are a large number of drawings that allow you to make furniture from plywood with your own hands. Such drawings can be easily found on specialized websites that are dedicated to making furniture from plywood with your own hands; in addition to drawings, you can see photos on such resources finished furniture from this material and the corresponding description for them.

Very often, plywood is used as a material in the manufacture of furniture intended for placement in the country house or in a children's room.

Such furniture is characterized by ease of manufacture and a high degree of environmental safety, which determines its high popularity.

Such furniture is characterized by ease of manufacture and a high degree of environmental safety, which determines its high popularity.

Large quantity Homeowners are interested in how to make furniture from plywood with their own hands. First, you should study what types of plywood exist and how to work with them.

The production of any type of plywood is carried out from veneer, which is glued together during the production process of the material with adhesive mixtures. The quality of the material obtained during production depends mainly on the material used adhesive composition.

The production of any type of plywood is carried out from veneer, which is glued together during the production process of the material with adhesive mixtures

Thanks to the glue, the panel acquires:

- high strength;

- increased mechanical elasticity;

- resistance to moisture;

- high resistance to environmental influences;

- resistance to open fire.

To make plywood, domestic manufacturers use veneer made from birch or coniferous wood.

Plywood, made from coniferous wood, has a beautiful pattern and is used exclusively for the production of furniture. To reduce the cost of the material during production, hardwood veneer can be used, on which a top layer of softwood veneer is applied.

Plywood made from birch wood has a contrasting structure and is monochromatic. When using birch wood, plywood is more expensive.

Important! Birch plywood weighs more than plywood, which is made from softwood.

Depending on the degree of processing, plywood is divided into 3 categories:

- material not subject to grinding - category NSh;

Bending strength of plywood

- material processed on one side - category Ш1;

- material processed on both sides - category Ш2.

There are 6 types of plywood, which differ in the composition of the adhesive component used in production:

- FC is produced using urea glue. The material can be used to make children's furniture from plywood for dolls with your own hands.

- FSF is manufactured using phenolic resins and is used to construct furniture items that are used in rooms with high humidity.

Plywood characteristics table

- FOF is a material with a laminated film coating that is highly moisture resistant.

- BV is a type of material not used in the construction of furniture.

- FBA - material with no high level resistance to moisture, not used in furniture production.

- FBS, BS, FB are produced using bakelite-based glue or varnish.

Note! Based on the presence of defects and natural defects in the wood used, the produced material is divided into 5 grades.

Grade E material is considered to be of the highest quality.

Rules for processing materials in the manufacture of furniture

To make furniture with your own hands from plywood, you should cut the sheet before starting operations. When cutting the material, accuracy should be observed, since in the future this parameter can affect the entire furniture assembly process.

A sharp knife is used for cutting thin plywood; a jigsaw is recommended for cutting medium-thick plywood

At the same time as cutting accuracy, it is necessary to be careful when cutting and avoid the formation of chips. The absence of chips increases the design quality of the structure. To cut the material, use a jigsaw or an electric circular saw. In order to prevent chips from forming on the front side, when working with a jigsaw, it is necessary to apply a drawing to the front surface of the material, and when using a circular saw, the drawing is applied to the reverse plane.

In order to completely get rid of the slightest chips, you need to cut through the top sheet veneer to the width of the jigsaw blade or saw. To perform this operation efficiently, the first pass is made without strong pressure as a mark, and then another 2-3 passes are made with a knife with strong pressure.

Cutting and cutting plywood sheets is best done along the grain. With this cutting method, the smallest number of chips appears when all the requirements of the technological operation are met.

To cut thin plywood, a sharp knife is used, a jigsaw is recommended to be used for cutting medium-thick plywood, and if thick material is used when assembling furniture, it is recommended to use a special circular saw for cutting it.

If, when constructing furniture from plywood with your own hands, plywood from soft varieties wood, then special washers should be placed under the fasteners, which reduce the negative impact of the fasteners on the wood; photos of how to properly install special washers can be viewed on specialized websites dedicated to assembling furniture structures with your own hands.

When constructing children's furniture from plywood with your own hands, you should special attention pay attention to the processing of end elements, this is required to minimize the likelihood of injury when children use the product.

Features of material processing in the manufacture of kitchen furniture

Designing furniture to furnish the kitchen space requires care when drawing up drawings and assembling structures.

DIY plywood set

When assembling kitchen sets, it is recommended to use moisture-resistant types of material that have high resistance rates. The fact is that the kitchen is a room with increased level humidity, and this in turn can negatively affect the plywood.

When designing furniture, it should be taken into account that kitchen area There is a room ventilation system and other utilities that must be hidden and at the same time must have free access for repair work.

When designing floor cabinets, you should remember that their height and depth should be calculated taking into account the size of the countertops used when assembling the furniture.

When calculating the parameters of the side walls, the thickness of the doors used in the furniture design should be taken into account.

When assembling kitchen furniture, special attention should be paid to the corners. wall cabinets, since the assembly of these elements is fraught with difficulties

When assembling kitchen furniture, special attention should be paid to corner wall cabinets, since assembling these elements is fraught with difficulties.

You can see in detail how to design plywood furniture with your own hands in the video, which is easy to find on specialized websites dedicated to creating furniture yourself.

When constructing floor-standing cabinets, the best option would be to use solid thick plywood boards.

DIY furniture assembly technology

Using plywood, you can make almost any furniture for your home; it could be, for example, a bed or a rocking chair, a closet, both floor-mounted and wall-mounted.

Using plywood, you can make almost any furniture for your home, it could be, for example, a bed or a rocking chair, a closet, both floor-mounted and wall-mounted.

Such furniture is distinguished by its originality and uniqueness, which can surprise any person. Furniture made with your own hands from plywood can become the pride of the home owner.

To design a bed, you will need to prepare a drawing or sketch indicating the dimensions of all structural elements.

After preparing the sketch, it is necessary to prepare a plywood sheet with a thickness of at least 18 mm, the length of the workpiece should be 3 m, and the width 1.5 m. A sheet 2 m long is cut from a single sheet. This cut will subsequently serve as the bottom in the design of the bed. After preparing the plywood sheet that serves as the bottom of the bed, the ends of the workpiece should be thoroughly processed with sandpaper. The remaining cut from the initial blank can be used in the manufacture of such a structural element as the head of the bed.

If in the process of constructing furniture a sheet that does not have lamination is used, then after assembling the structure, the head of the bed is covered with stain or paint and left until completely dry.

Construction of a bed frame and its decoration

The construction of a frame base requires a careful approach during design and assembly. At the design stage, accurate calculations of design parameters should be carried out. The bed frame is made of timber. For assembly, you need to prepare 2 pieces, each 2 m long and 2 pieces 1.5 m long. In this case, you should take into account the width of the beam. The bars should be connected to each other using screws or nails.

The bed frame is made of timber

The previously prepared bed bottom is attached to the prepared frame. The bottom should be secured using long bolts. The bed legs are fixed to the inner corners of the structure. The legs of the bed should be made of timber.

Decorating a bed made of plywood is the last stage of DIY furniture production.

The headboard of the bed should be installed using long bolts. The headboard can be decorated using fabric intended for furniture finishing. In addition, the headboard can be finished in any way. in a convenient way. If desired, during the finishing process, fabric is used, under which foam rubber is placed; this approach to finishing the headboard makes it more contoured and embossed.

Construction of a rocking chair from plywood

More often furniture showrooms offer their consumers designs of rocking chairs designed for one person. Those who like to design their own furniture for their home can make this piece of furniture for two people.

All photos from the article

Plywood is not only unique building material, but also an excellent basis for making various crafts. Moreover, for this you will need a minimum of tools - a manual or electric jigsaw, the plywood sheet itself, and the result largely depends on human imagination.

Scope and advantages of plywood sheets

There are many options for using this material; in general, we can distinguish the following methods of using plywood:

- floor covering, and plywood can be used both for leveling and for insulating the floor;

- wall cladding - unlike drywall, plywood sheets are much stronger, although they weigh more, and are susceptible to moisture;

- arrangement of formwork when concreting foundations or making concrete blocks;

- arrangement of a solid base for soft roofing material, for example, under bitumen shingles;

- making various crafts, ranging from simple figurines to complex mechanisms, in which even moving parts are made of plywood. In general, in the question of what can be made from plywood with a hand jigsaw, the only limit is a person’s imagination and perseverance, so the scope for creativity is simply limitless;

- Full-fledged furniture can also be made from plywood, and its strength is in no way inferior to ordinary wood.

This material also has a number of advantages:

- even thin material has outstanding strength, due to the layered structure of the material. consists of several layers of veneer, and when gluing, the fibers of each layer are located at an angle to the previous one, so that such a sheet works just fine when bending;

- due to the use of adhesive mixtures when gluing layers of veneer, plywood is not afraid of moisture;

Pay attention! For use inside the house, you should choose sheets marked FC, this means that urea glue was used when gluing, which does not contain phenolic compounds that are dangerous to human health.

- You can buy a large sheet of plywood for about 500-700 rubles; it will be enough for several dozen complex crafts. So the price can also be considered an advantage of this material.

Rules for working with a jigsaw

When making any craft, you can’t do without cutting plywood with a jigsaw (manual or electric).

There are several rules in this matter that should be followed in any case:

- The plywood sheet itself is quite flexible, so if you try to saw it without a rigid backing, it will bend and it will be difficult to adhere to the drawing line. The stand can be made from an ordinary thick board with a hole in the center for a jigsaw file; it is attached to the work table with an ordinary clamp;

Pay attention! It is important to correctly install the file into the jigsaw before starting work. The direction of the teeth should be as shown in the figure.

- when cutting plywood with a jigsaw, the tool itself is held perpendicular to the sheet, there is no need to press hard on it;

- when working, you should turn not the jigsaw, but the plywood sheet itself;

- It is unlikely that when cutting figured shapes it will be possible to do without sharp turns and sharp corners. In order to obtain a sharp turn or an acute angle, the instructions require moving the jigsaw up and down in one place, gradually turning the plywood sheet so that a small hole is formed in it in which the file will turn freely. After this, you can cut out the desired angle;

- You may also need to cut out blind holes that cannot be approached from the edge. In this case, you can simply drill a hole in it, insert a file into it, and only then secure it to the jigsaw frame. After this, you can cut a hole of any shape.

It is not necessary to make plywood products with a jigsaw using hand tools, the same quality can be achieved using power tools.

Examples of DIY plywood products

It is physically impossible to consider all the options for plywood crafts in one article. But it’s still worth stopping at a few interesting options.

The simplest plywood crafts

As a test, you can try to make a couple of simple crafts consisting of only one element. There are many options, for example, you can try to cut out the outline of an animal from plywood and then paint it in the desired colors.

This level of complexity is suitable even for children; the work will be performed in the following sequence:

- first, the desired picture is simply printed on plain paper (or drawn by hand);

- then you need to transfer the outline of the image onto the plywood. You can do this using carbon paper or simply cut out the image and paste it onto a wooden base;

- then we simply carefully cut out along the contour; even a preschool child can make such plywood products with his own hands using a jigsaw;

- After cutting, all that remains is to sand the figure and paint it. In order for the figurine to look bright, it is advisable to use a wood primer and only then paint it.

You can complicate the task a little and try to make a figurine consisting of several elements, for example, a Christmas tree or a snowman. A plywood Christmas tree with a jigsaw will consist of 2 parts connected like a tongue and groove.

To make it, you just need to trace 2 contours of the future Christmas tree on plywood and provide grooves in both elements. In one part, the cutout is made from the top, and in the second - from the bottom, the size of the cutout is up to the middle of the height of the future Christmas tree.

After cutting, you will need to sand the surface of the plywood and walk along the edge to remove burrs and smooth out any sharp edges. The dimensions of the grooves in the lower and upper parts must correspond exactly to each other.

Pay attention! Many do-it-yourself drawings of plywood products using a jigsaw can be found on the Internet, for example, on our portal. This is much more convenient than drawing yourself.

After mastering figure sawing, you can move on to crafts consisting of several parts. As an example, we can give a figurine of a snowman, consisting of a torso, a head, two legs and arms; all these elements will be connected to each other with an ordinary thick thread.

The basic principle remains the same - we draw up a drawing, cut out individual parts from a plywood sheet, and then move on to combining them. In addition to working with a jigsaw, you will have to drill thin holes in the plywood in order to thread the thread through them.

A plywood snowman is assembled into one piece using a jigsaw; you can put a small bright scarf around your neck. As with other crafts, the color of the figurine is of great importance; the coloring should leave the impression that the snowman has just been brought into the room from the cold.

The options are relatively small and simple crafts There are many, and you can always make drawings of plywood work with a hand jigsaw yourself or simply find them on the Internet.

Making the task more difficult

If you have a jigsaw, you can try to take on a larger task. It is relatively easy to make an elegant frame for a picture from plywood, and the picture itself can be made entirely of plywood.

A picture made of plywood can be easily obtained by combining light plywood and a dark background. You just need to cut it out on the sheet light color the desired outline and then fix it in a frame on top of a dark background. Due to this, the desired effect is achieved; externally, such paintings look no worse than ordinary ones, even more unusual, because traditional painting is more widespread.

As for the technology, to make a picture you only need a template with the location of the cutouts. You can make it yourself; to do this, just make the image you like black and white, add contrast and manually mark the position of the cutouts. The number of layers of plywood of different shades is limited solely by the skill of the author.

Thin plywood is also suitable for making a frame for a picture or photograph, and frames made from plywood with a jigsaw can also be solid, that is, cut from one piece of plywood. The simplest plywood frame is a closed plywood contour (rectangular, square or oval) with figured sawing along the outer perimeter.

An electric jigsaw is used by home craftsmen to create beautiful products from plywood and wood. Such crafts are used for a variety of purposes. They can be decorative or serve as household items. Every home craftsman who is interested in this activity should know the features of working with the tool.

You should learn more about how to use the “miracle jigsaw” and what can be cut with it.

Subtleties of working with a jigsaw

The jigsaw is universal device, which is used for cutting figured products from various materials. All you need is to choose the right canvas. It is important to understand how to cut out shapes complex shapes. Many novice craftsmen need to figure out how bevels on boards and various components of crafts are made. Electric jigsaws work best when cutting softwood. However, the thickness of the elements from which cutting is performed should not exceed 3.8 cm.

Blades that will be inserted into a jigsaw quite often bend and leave beveled edges. A straight cut is usually achieved with a well-sharpened blade. However, you should not put too much pressure on the tool while working.

You should first start the saw at the highest speed, and then select the blade angle. This will result in fewer chips. In materials that are highly brittle, it is necessary to drill holes. This will allow you to saw off the workpiece without unnecessary risk. As a result, there is no chipping of the part.

To ensure fast cutting, coarse blades should be used. However, it should be taken into account that when choosing such consumables, it will be more difficult to sand them later. Blades for electric jigsaws are made in such a way that the cut is made when the blade moves upward.

Choosing the Right Blade

Choosing a blade for an electric jigsaw is a major consideration when cutting wood and plywood. Often a jigsaw lies idle in a home craftsman's household. However, when you need to make a complex pattern, this tool is more necessary than ever.

Quite often, an electric jigsaw is used as a tool for cutting a hole in a countertop or when installing a kitchen sink. This tool is also used for cutting metal. When using other saws, it is often impossible to complete the assigned tasks. A jigsaw is a universal device. Both beginners and experienced people can work with it home handyman. As a result, you can get excellent results using different materials - plastic, wood, plywood.

How to use the tool

A jigsaw is used for a variety of tasks. Its main function is to cut curved shapes into wooden products. Getting smooth curves using this tool is quite easy. The base of the tool should be kept level on the workpiece. When the preparation is completed, you can begin the main work. Then the engine is turned on and the device is slowly moved along a pre-marked line, at a distance of 2 mm from it. Fine sanding is done later.

The saw should be moved at such a pace that the blade can easily cut through the material without any deflection. A jigsaw works great when cutting boards crosswise. A stop must be used if a perfect cut is required. Bevel cuts are fairly easy to make using a jigsaw. Before work, it is necessary to firmly secure the workpiece.

If an oblique or vertical cut is performed, the distance between the blade and the fence is set to the same as on circular table. When it is necessary to make a precise and long cut, it is difficult to work with a jigsaw. In this case, first use a circular saw. The final cutting of the element is performed with a jigsaw. It must be pressed firmly against the inside of the marked line.

Where to start

First is well organized workplace. Fulfilling this condition is especially important for high-quality cutting. If the space is arranged correctly, work will be convenient and comfortable. This condition is necessary to create a quality product.

The thrust structure is a special machine. People call it “swallowtail”. This table is made from boards rectangular shape. It has a wedge-shaped incision that goes into work area. The dovetail is attached to the edge of the table.

An electric jigsaw can be used while standing or sitting. The workpiece should be located at a distance of 40 cm from the eyes. It is necessary that the lighting lamp be installed in front of the master. It is placed at an angle to the surface.

Tool preparation

The saw blade in a jigsaw must be fixed in a strictly vertical position. The teeth should point down. Before work, you need to stretch the fabric well. The degree of tension must be adjusted by compressing the frame. The device must be rested against the edge of the table. Then you should tighten the lambs with pliers. When straightening the frame, the canvas will stretch.

To cut out parts with a jigsaw small size, or shapes with sharp contours, you need to choose small files. In this case, it is necessary to use canvases with a large number patterns per inch. When using them, the jigsaw does not jam when making turns. The cut is created neat and thin. If large-sized plywood products are made, it is necessary to use blades with large teeth.

How to cut with a jigsaw

To obtain an accurate cut, a number of conditions must be met:

- The hand holding the jigsaw should only move vertically.

- All movements must be made as smoothly as possible, without jerking. In addition, they must be performed with maximum amplitude. This is necessary to use the entire canvas.

- With the second hand, the workpiece turns smoothly during operation.

- Do not put too much pressure on the workpiece with the saw. Side pressure on the blade is unacceptable.

- Artistic sawing is carried out only when the file moves from top to bottom. For this reason, the reverse movement must be performed without pressure.

When working with a hand jigsaw, it must not be guided along the marked line. The canvas should be drawn along the inside of the contour. This is due to the presence of a kerf after sawing. After completing the work, one of the clamps should be loosened. The frame of the device should not lose its elasticity.

Jewelry box

You can make a beautiful and spacious jewelry box for Valentine's Day or International Women's Day. To complete such a craft, you will need to use an accurate drawing. The work is divided into several stages.

Preparing the work area

Before you start cutting out the parts of the box, you should prepare your workspace. A special table is installed for this purpose. The craft will be created on it. In this case, the following rules are observed:

- There should be no unnecessary items at the table while working.

- The cutting device should always be at hand. A specific place is reserved for it.

- Workbench. It is placed in a ventilated area. The room should be light and spacious.

However, it is not always possible to install a table for cutting with a jigsaw in the right place. TO ordinary apartment The workbench is usually placed on the balcony if it is insulated. At the same time, you can work on crafts in any weather.

Plywood selection

For the box you need to use a plywood sheet. When choosing a workpiece, you should pay attention to defects that often appear - cracks or knots. The workpiece is selected with a thickness indicated in the diagram. To transfer the drawing to the material, you should:

- Sand the workpiece with sandpaper. You should start with coarse-grained material. This treatment ends with fine-grain sandpaper.

- The surface must be level. To do this, you need to fix the sandpaper in the sanding device. If you don't have one, you can take a small block and wrap it in sandpaper.

- Grinding is carried out along the layers of wood.

- The workpiece is ground until its surface becomes as smooth as possible.

After such preparation, you should transfer the craft template onto it.

Transferring the template to a plywood sheet

Before starting sawing, you should transfer the prepared drawing to a plywood blank. First you will have to print the drawing on paper. To transfer, you must have tracing paper and a pen. First, the template is attached to the workpiece with tape. Having a blank in front of you, you should think about how to cut out the different elements of the box, saving the available material as much as possible.

Sawing out the box

When cutting, you need to adhere to some rules:

- The jigsaw should be positioned perpendicular to the product.

- It is necessary to ensure that all movements are performed as smoothly as possible. You should not rush while cutting - this way you can make a mistake and ruin a piece of material.

- It is necessary to use a sawing table.

- First you need to cut out the internal elements. Only after this they begin cutting the contour.

When leaving the cutting line, it is necessary to correct the line with a needle file while assembling the product.

Advice! During work, your hands will get tired. In this case, productivity drops significantly. Fingers and eyes get seriously tired. All this can lead to hand injuries. This is why it is necessary to take breaks from work.

Assembling the box

Before assembly, you must familiarize yourself with the product drawing. Matching the pieces of a jewelry box does not require any delicate work. Before gluing different elements you need to make sure that they can be put together without problems. After several assemblies of the product without any difficulties, you should begin gluing the parts. Typically, a PVA composition is used for this purpose. During operation, it is necessary to eliminate any glue leaks.

Assembling a steam locomotive model

When the material is prepared and the drawing is printed, you should begin the process of transferring the diagram to the workpiece. In this case, it is necessary to take into account some operating rules. Many home craftsmen tend to transfer a drawing onto plywood using only a copy and a pencil. However, you can also use the “Black Ribbon”. When choosing this tool, the drawing is glued to the workpiece. Then the diagram is washed off the plywood with water, leaving only the marking lines.

Then you can make holes in the parts of the future locomotive. The parts of the locomotive contain parts of grooves cut out from the inside. To make such elements, holes should be made in them with a hand drill or an awl. The holes must be at least 1 mm in diameter. To avoid damaging the table surface when creating holes, you should place a board under the workpiece.

Now you can cut out the parts. You should not rush when cutting. The basic rule is to hold the jigsaw at right angles to the workpiece. All elements must be performed smoothly, avoiding unevenness.