Placement of fire sensors. Installation of a security and fire alarm system: how to install it correctly. Ceiling barriers and obstacles

Installation work fire alarm must be performed by companies that are licensed to carry out this type of activity.

In addition, all equipment used must also be certified and have appropriate documentation and technical passports.

Requirements for installing fire alarms.

In order for an automatic fire alarm system to be effective and to function smoothly throughout its entire service life, the possibility of reconfiguration must be taken into account when designing it.

This is necessary for several reasons. In a building where a fire alarm is installed, major or cosmetic repairs may subsequently be carried out. renovation work. There is a fairly high probability of redevelopment, changing the purpose of the main premises or changing location production capacity, machines and mechanisms.

All this may lead to the need to change the original layout of detectors and control panels. Based on this, special requirements When installing a fire alarm, requirements are applied to the location of cable networks, the cross-section of wires, their capacity, etc.

When designing and installation work It is necessary to provide for the possibility of scaling or modifying the automatic alarm system.

When purchasing and installing a control panel, it is also necessary to take into account the likelihood of a change in the topology of cable networks and an increase in the number of fire detectors (connected loops).

BASIC REGULATIVE DOCUMENTS

Most production and commercial properties, buildings of public, municipal and national infrastructure cannot function without being equipped with a fire alarm.

In this case, to put the system into operation and operate it, the following set of documentation is required:

- project for installation and installation of equipment;

- certificate of commissioning work, signed by representatives of the customer and the organization performing the installation;

- agreement on provision maintenance;

- act of putting the fire alarm system into operation.

Maintenance must also be carried out in accordance with RD 009-01-96, which defines the main types of work and the frequency of their implementation. It is mandatory to have a journal at the facility to record the maintenance and repair of alarm and automation systems.

The design and installation of automatic fire alarms is carried out in accordance with the following legislative acts and regulatory documents:

- Federal Law No. 123 adopted on July 22, 2008, as amended on July 29, 2017;

- Federal Law No. 315 adopted on December 1, 2007, as amended on July 3, 2016.

The list of buildings and structures that are subject to mandatory equipment with fire alarms and warning and evacuation control systems, as well as the procedure for performing installation work, are defined in the codes of practice of the Russian Ministry of Emergency Situations:

- SP 5.13130.2009 dated March 25, 2009 N 175;

- SP 3.13130.2009 dated March 25, 2009 N 173.

If the facility has a system fire alarm is missing or installed with significant violations of current regulations, the owner of the building or the head of the organization will be held liable in accordance with Decree of the Government of the Russian Federation No. 390 dated 04/25/2012 as amended on 03/06/2015.

* * *

© 2014 - 2019 All rights reserved.

The site materials are for informational purposes only and cannot be used as guidelines or official documents.

The reliability and performance of the fire extinguishing system largely depends on the correct installation, compliance with the rules and requirements for the systems. One of the mandatory conditions is the installation standards for fire detectors, which depend on the type of devices and the characteristics of the protected area.

Calculating the distance between individual detectors and determining the location of their installation is a labor-intensive and important issue that designers have to solve from scratch at each site.

Codes and regulations governing the installation of fire detectors

To guide and control the installation of fire-fighting equipment, various regulations are used, which define the types of detectors, requirements for them and standard indicators that the distance between fire detectors must meet.

Main normative document in this area are NPB 88-2001, approved by order of the GUGPS 04.06.01, which define the norms and rules for the design of fire extinguishing installations and alarm devices.

It is also necessary to take into account the Code of Rules 5.12.130.2009 dated March 25, 2009, dedicated to the rules and regulations for the installation of automatic fire extinguishing systems, taking into account subsequent changes, in which the rules for installing fire alarm sensors are set out taking into account the characteristics of various ceilings.

All current standards and requirements are aimed at ensuring high level fire safety and making the most efficient use of firefighting equipment.

The disadvantage of these documents is their theoretical nature, i.e. they contain only a list of requirements. For practical use, various European standards are often used, which describe the nature of the ongoing processes of combustion and fire extinguishing from the point of view of their physical nature. Thus, the British standard BS 5839 allows you to simulate different stages of a fire and choose a solution for each specific situation.

Rules for placing smoke devices

There are several various types smoke detectors that are installed in various rooms, and for which special rules apply for measuring the distance between them or from the wall to the detector.

- Optical point smoke devices are used on small format objects, such as residential apartments and homes, hospital premises, hotel rooms.

- Linear fire alarm installations are intended for spacious facilities such as warehouses, halls and halls public premises, airport or train terminals.

- aspiration detectors are installed in rooms cluttered with documents and materials, for example, in libraries, museum storerooms, archives.

For reliable operation of point and aspiration devices, fixed fixation under the ceilings is necessary, i.e. where the possibility of vibration is minimal.

The coverage area of one detector depends on the ceiling height:

- up to 3.5 meters – 85 m2;

- from 3.5 to 12 meters – 55 m2;

- over 12 meters - a two-level placement is required (on the walls and ceiling) and the simultaneous use of point and linear models.

The distance between fire alarm devices should not exceed 9 meters.

Linear devices are placed on walls opposite each other at a distance of 9 meters. For high rooms (from 12 to 18 meters), two rows of sensors are used and the minimum distance between levels is at least 2 meters, with the bottom row located above 4 meters from the floor level, and the top row no closer than 40 cm from the ceiling.

At suspended ceilings smoke detectors are installed between two ceilings and directed to the ventilation exits.

Installation of flame detectors

The main requirement affecting the placement of fire flame detectors is the mandatory optical accessibility of the territory, i.e. the absence of obstacles that interfere with the fixation of the resulting flame.

The devices are mounted indoors and outdoors, they can be installed on the ceiling, wall or on equipment. For installation, the distance is measured not between fire detectors, but from the device to the corners. This indicator has limited limits:

- 10 cm for ceiling mounts

- 30 cm for wall appliances.

Also, it is recommended to set the placement of sensors from each other in a rectangular room according to the following parameters:

Placement of thermal linear detectors

Thermal linear detectors react to vibrations temperature regime. They are manufactured in the form of a thermal cable, sensitive along the entire length. The distance between fire alarm sensors inside buildings is 10-12 meters. When installing outside buildings (under canopies), installation rules require that a distance from the canopy to the cable be maintained at least 50 cm.

Heating appliances are used in rooms with a large area and high ceiling, for example, in stadiums, inside warehouses, production workshops.

The main requirement is reliable fixation to the wall, ceiling or well stretched without fastening so that fire safety networks are not at risk of damage. All laid cables are connected at the location of the control point, where all information about the fire threat is sent.

Placement of hand-held devices

Manual sensors are activated directly by a person, so the placement of fire detectors is determined by ease of access to them.

They are installed on the walls of the room at a height of about one and a half meters from the floor, i.e. inaccessible to accidental inclusion by animals or children, and located at the level of vision of most people.

Installation requirements are the absence of furniture or equipment blocking access to hand-held devices. Places for installing sensors must be publicly accessible and not have individual locks - stairs, corridors, halls. The distance between installation points should not exceed 50 meters, and, if external territories are controlled, then 150 meters.

“Pay attention!

It also takes into account the distance to the lamp and its power, which affects the level of illumination of control points.”

Gas detector placement

When using a fire detector, the main indicator is physical characteristics gas and the room itself, i.e. the probable directions and speed of gas propagation are taken into account. Typically, gas appliances are placed directly next to gas appliances containing toxic or flammable gases that may leak. Objects where it is decided to install gas fire detectors are industrial premises or special gas distribution points.

Placement of autonomous detectors

The peculiarity that an autonomous fire detector has is that it activates independently and does not require human presence or control. Place of use - residential premises, hotel rooms, sanatoriums, holiday homes and so on.

The standard area under the control of the device is 30 square meters, and if the space or ceiling plane has complex geometry, then this indicator must be reduced by a quarter, i.e. up to 23-25 meters. Taking into account the characteristics of typical protected objects, devices can be installed one per unit area.

For reliable operation of the equipment, avoid direct exposure to the sun, as well as closed corners, with unreliable ventilation.

The rules provide ceiling installation, and if this is not possible, the installation standards for wall fire detectors provide for a distance from the ceiling ranging from 10 to 30 cm.

Installation of light, sound and voice alarms

In addition to detectors that transmit information to control panels, various sirens are widely used, i.e. devices that convey alarm signals and fire information to all people in the danger zone. The main task of this equipment is to notify people of the need to evacuate when sensors detect fires (smoke, flame, jump in thermal level).

Annunciators transmit signals using:

- light indication,

- voice (speech) alerts,

- sound signals (sirens, bells).

Each type has its own requirements.

Light indicators require a place accessible for viewing, and a maximum distance of 60 meters between the nearest panels.

Sound and speech devices can be located both indoors and outdoors, and are located at a height of about 2 meters from the floor.

Distance between alarm loops

Fire alarm loops are designed to transmit signals from the sensor location to the control point or the location of the siren.

Requirements for installing loops - the ability to convey information to the end point. Those. they must be protected from open flames or high temperatures.

Installation limitation - distance to electrical cables not less than 50 cm, and in exceptional cases - 30 cm is allowed. This requirement is due to the following reasons:

- preventing accidental activation of the fire system;

- protection against damage when the electrical network is shorted.

The installation standards for fire detectors are mandatory for use. They provide maximum efficiency operation of equipment and creation of conditions for fire safety.

On at the moment Security and fire alarms have become quite common, increasing the level of protection of all kinds of objects. Thanks to its “many-sided” functionality and component composition, not only a fire is detected in a timely manner, but also careful control is maintained over the protected area. Such a device is quite complex and expensive to install and maintain, but you will not find an electronic device that is so reliable.

How does a fire alarm system work?

A fire protection system is a whole “set” of different technical devices that provide fire safety various types buildings, equipment, people, as well as material assets. It includes two systems: warning people in the building and a fire alarm.

OPS device diagram

OPS device diagram

Thanks to the fact that a software and hardware dispatcher was installed, you will always see the source of the fire on the site plan. If the semi-automatic mode was set on the alarm system, then after an alarm signal is received from it, the security service must turn on the fire warning system for personnel and at the same time activate visual, voice, and voice messages.

When a fire alarm in the building is confirmed, the main signal will be transmitted to the ACS - the “message” system and thereby put all alarm elements into emergency evacuation mode. The signal will also be sent to the control system of various utility networks of the building, after which they will switch to fire hazard operating mode.

A fire device operating in automatic mode performs the following functions:

- Identification of the fire zone;

- Detection of a lesion after 2 confirmations from the moment of registration;

- Monitor network problems on short circuit, as well as a cliff with reference to the building plan;

- Detection of the lesion at the initial stage;

- Management of different blocks with the output of the obtained results to the dispatcher workstation;

- Viewing the fire safety status of building areas on a detailed and general plan, which are displayed on the dispatcher’s console in text and graphic format.

Features of design and calculation

Design of an alarm system is the main stage on which the effective operation of the entire system depends. This work should be done by professionals, since this is a complex scheme with a number of calculations, a significant number of devices and their locations. However, since they are all connected to each other by a cable, it is therefore necessary to design the trajectory of further installation. In addition, one must take into account possible nuances, which are being developed in a project to eliminate emerging threats.

High-rise building security design project

High-rise building security design project

However, the development of an environmental protection project is a subjective process, since each object must be carefully studied taking into account the characteristics of use, as well as plans. Moreover, it is necessary to evaluate:

- Design complexity;

- Size of rooms;

- Specifics of the layout.

Attention should also be paid to places where outbreaks are most likely to occur. The design of the fire safety system is carried out taking into account the PUE, as well as DSTU. The project includes huge amount various works:

- Technical specifications, which take into account all the client’s wishes;

- Study of premises;

- Creation of a standard project with all estimates for the work performed;

- After agreeing on all the nuances with the client, all documents and estimates are signed;

- Installation and testing of operation of the alarm system.

In the process of preparing for the installation of an alarm system, it is necessary to carry out many calculations, thanks to which you can choose the most ideal type of device and at the same time avoid additional costs, for example, with servicing detectors or installing the system itself.

Standard project security and fire alarm system

Standard project security and fire alarm system

Most important stage calculations is to determine the ideal capacity for the energy source itself. In other words, you need to decide which type of power source is most suitable for connecting the detectors. The source can be not only rechargeable batteries, but also ordinary batteries.

Security and fire alarm devices

Security and fire alarm devices

The required source capacity is usually indicated in the fire alarm operating instructions itself. Therefore, you need to check the value on the battery case with the available information in the instructions. If the power capacity is not enough, then buy a more powerful device. If you connect several batteries, you need to make sure they are the same voltage.

Also check the required wire cross-section for the OPS and pay attention to the battery capacity characteristics for different modes work (anxiety, expectations). Next, you need to sum up these values, after which you will get the overall battery capacity of your OPS.

Types of systems

Today there are a huge number of different fire alarms of all possible levels of complexity. However, they all perform one function - they control the protected object using detectors. Most modern fire systems can remotely transmit a signal to the main security console and even perform many other service functions. But their main task is the timely detection of a fire on the territory of the facility or illegal entry. Depending on the method of determining the fire threat, systems can be divided into the following types:

Main types of sensors

Fire detectors or sensors are special devices that allow you to record certain properties fire ignition with its initial detection and further prevention. Also, sensors are the main element of the entire alarm system, ensuring fire safety. The reliability of a detector is determined, in general, by effective work systems, and they are divided into the following types:

Heat detectors

They react to changes in air temperature and can be divided into:

A heat detector should only be used if heat is the main symptom of a fire.

Smoke detectors

They help detect the presence of smoke in the air, and they work on the principle of dispersion infrared radiation on smoke particles. The disadvantage of smoke detectors is that they are capable of triggering even with a significant amount of dust and steam in the room. But meanwhile, they are very popular, although smoke sensors are not used in smoking rooms or very dusty rooms.

Smoke detector OPS

Smoke detector OPS

Flame detectors

They are triggered only by an open flame or a smoldering hearth. They are installed mainly in rooms where fire may occur without the initial release of smoke. They are also able to detect a fire in the initial stages, that is, in the absence of most factors, such as temperature changes and smoke. Flame detectors are used in production premises, characterized by significant heat transfer and dustiness.

Flame detector OPS

Flame detector OPS

These sensors are suitable for various applications, as they react to smoke, heat and even gas in the air. They operate on the principle of identifying a series chemical reactions. These detectors contain carbon monoxide particles, and the automatic settings can determine the ideal temperature of the monoxide, which, when changed, generates an alarm.

Gas leak detector of the alarm system

Gas leak detector of the alarm system

Combined sensors

Capable of detecting signs of fire in several ways at once. Basically, these are devices that have the functions of not only a smoke sensor, but also a heat sensor, thanks to which it is possible to specifically identify signs of fire and then notify people.

Combined alarm system detector

Combined alarm system detector

Installation and connection of security and fire alarm systems

Where and how to install fire detectors

The standards for installing fire alarm detectors are quite liberal: between sensors is 9 meters, from the wall - 4.5 meters. However, this placement is made solely for the sake of comfortable configuration of a particular fire system. In this regard, we can conclude that the installation and location of detectors is a more complex matter.

Security and fire alarm installation diagram

Security and fire alarm installation diagram

When installing sensors on walls, the distance must be at least 200 cm, otherwise they will give a false alarm because they will end up in a “smoke pocket”.

The sensitivity of the detector depends directly on the distance of the source of danger and it does not cover the entire hemisphere. In an empty room, the area monitored by the sensor depends only on the ceiling height.

By flame:

- Up to 15 sq.m. – from 6 to 9 meters;

- Up to 20 sq. m. – from 3.5 to 6 meters;

- Up to 25 sq. m. – 3.5 meters;

- More than 9 meters - it will be impossible to control, since the fire will become a fire, and the sensor itself will not work.

- Up to 85 sq. m. – this is up to 3.5 meters;

- Up to 70 sq. m. – this is from 3.5 to 6 meters;

- Up to 65 sq. m. – this is from 6 to 10 meters;

- Up to 55 sq. m. – from 10 meters.

However, accurate calculation of detector locations requires modeling on a PC or by a professional.

How the warning system works

When the detectors detect a fire, the fire warning system automatically turns on. According to their operating principle and composition, warning systems are divided into:

The notification function is implemented through output as well as input interfaces. To display information, alphanumeric and light indicators are used, as well as audible alarms.

Possible malfunctions after installation

Inadequate prevention is the main cause of fire alarm malfunctions. In other words, it is necessary to constantly carry out all preventive work. Smoke detectors often fail because various particles and other debris get into their chamber. However, there are cable breaks or system errors, which also cause malfunctions.

Considering fire system alarm system, the main problems are highlighted:

Often, significant damage to fire alarm systems is caused by dirty and heavily dusty work areas, high humidity or high temperature. Also, the reason for the failure of the alarm system is also trivial reasons, for example, broken cables, which is why the alarm can squeak, blink, and so on, even without a fire. But the most serious cause of problems is still the intervention of unqualified specialists, amateur activities, or the end of the service life.

How to remove a fire alarm yourself

If the alarm goes off for no reason, it can be turned off completely. The most basic option is to remove the power (battery) from the sensor or disconnect the control panel from the network.

Attention! In this case, the fire alarm will become useless and will not be able to warn you about a real fire.

In addition, many fire alarms are equipped with additional power sources and a button located on the front side of the sensor, which will also need to be turned off. When you press the button, the device goes into alarm mode, and the sound signal is reset automatically.

The fire alarm can also be turned off using a centralized control panel, but for this you need to know the password. If you cannot find out the cause of the device failure, then solve the problem radically - cut the wires that go to the sensor, but in this case the device will stop working altogether and will simply resemble a decorative element.

Video: how to connect an alarm system with your own hands

Human safety is a top priority, no matter whether he is at work or at home. This can be achieved by installing an alarm system in combination with other devices. But in order for the alarm system to work as efficiently as possible, it is necessary to adhere to certain rules for design, installation and operation.

Hello, dear readers of our blog, in which we, together with you, comprehend all the rules and requirements of fire safety in the Russian Federation, almost every time making our way through the regulatory jungle. Fire alarm installation - with for a long time the matter is necessary and justified.

Its functioning is ensured, first of all, by the correct placement of detectors on the territory of the facility. Naturally, there are standards for installing fire alarm sensors, and today we will look at and discuss them.

However, even designers have difficulties because modern design premises are often extremely intricate, and without understanding the physical processes possible during a fire, it can be quite difficult to determine the distance between the detectors, and even the location of their installation.

Let's make it clear right away: the detector is an integral part automatic installation fire extinguishing or warning systems. In most cases, they are installed on the ceiling, with rare exceptions on the walls, and must cover the entire area of the room with their effect.

If, in the event of a fire, the smoke from it spreads into the dead zone, the fire will spread until the temperature from it or the smoke reaches the sensors, but the damage caused will be much greater.

Smoke can also be dissipated by a draft, and its concentration under the ceiling will not be sufficient to trigger the sensor. The same can happen with temperature. It goes without saying that at some point the fire will reach the scale when all the sensors will send the necessary signals. But, again, a delay of even a second can be fatal.

All this must be taken into account when designing. And, you see, it would not hurt to find out what documents regulate these standards, which ones can be extremely useful, what the main regulatory indicators are and how to find a solution in difficult situation, for example, with an intricate design.

Our meeting today is extremely useful not only for customers, owners of buildings and premises, but also for the designers themselves. I am sure that they will also learn for themselves useful information.

For general information, let's clarify what a detector is, what a sensor is, which ones exist and which ones are used when equipping AUP objects or alarms when protecting objects in the Russian Federation.

What is a fire detector? They are often called sensors, but in fact the sensor is part of the detector, which, based on its indicators, generates a fire signal.

Thermal sensor is the most widely used in the vast expanses of our vast homeland. It is used in cases where the initial stage of fire involves heat generation, or in cases where the use of another option is impossible.

Smoke sensor - reacts to combustion products (smoke), and, depending on the model, operates in the infrared, ultraviolet or visible spectrum. By the way, it is detectors equipped with such sensors that should be used to protect administrative and household facilities.

There are other options, for example, gas or flame. It’s not difficult to guess what they react to, but the scope of their application is specific, so we will omit them in our story. It’s better to focus on the documents regulating the standards for their installation.

Regulatory acts

Today the norms specified in the set of rules SP 5.13.130.2009 are in force. The requirements for various rooms: among other things, with sloping ceilings, lattice ceilings, non-standard shapes, etc. It will also be necessary to amend this set of rules No. 1, which has been in effect since June 20, 2011 - many adjustments necessary for design have been made here.

The disadvantage of these documents is that, strictly speaking, they are limited to requirements alone. And it is often necessary to simulate possible processes occurring during a fire in order to adequately draw up a project. Unfortunately, the set of rules does not contain their description.

Therefore, many experts resort to European standards, for example, British BS 5839, which first describes the physical processes that occur during a fire in different situations, that is, modeling the initial stages of a fire, and then a solution is proposed. Therefore, it is obvious that it would not be superfluous to arm yourself with this document.

Well, now, let's figure it out.

Sensor distance

What type of detectors need to be installed at a particular facility is described in sufficient detail in Table M1 “Selection of types of fire detectors depending on the purpose of the protected premises and the type of fire load.” And, as a rule, there are no problems with this.

But installing point detectors correctly, observing all the requirements and maintaining the required distances, often raises a number of questions.

So, the area covered by one detector directly depends on the height of the room. Accordingly, the distance between them is also variable, as is the distance from the wall, where dead zones most often form due to defects.

If, suppose, you are the owner of a fairly standard room, the ceiling height of which does not exceed 3.5 m, then the smoke sensor should be located 4.5 m from the wall, and at a distance of 9 m from each other (Table 13.3), and one detector here controls 85 m 2.

The higher the height, the smaller the controlled area, and the closer the distance of the sensors to each other should be - see paragraph 13 “Fire safety systems” of SP 5.13.130.2009.

If we are talking about a heat sensor, then the indicators are slightly different: under the same conditions (H - ≤3.5 m) - the distance between the detectors is 5 m, from the wall 2.5 m, and the controlled area is no more than 25 m, and also , with increasing altitude, it is necessary to bring the sensors closer together (Table 13.5).

The lack of information here is that the range of each emitter is not indicated, but only the required distance between them. When you are faced with duplication, in such a way as to not only fulfill the requirements, but actually provide yourself with fire protection, with non-standard forms of premises - you will feel it.

But if we start from the fact that high-quality detectors from foreign manufacturers are installed, then we can talk about a radius of 7.5 m, specified in European standards.

All Russian requirements are based, in fact, on the simplest, most obvious model of the spread of heat and smoke in a room with horizontal ceilings at the beginning of a fire: from the source, a stream of smoke and a flow of heat rise strictly upward and spread purely in the horizontal plane.

It’s a little more difficult with narrow rooms, such as a corridor. Here it should already be taken into account that it is precisely because of the limited space that the specific density of smoke will increase. What does this mean? Judge for yourself: the narrower the room, the denser the smoke will spread, which means the greater the distance can and should be maintained between detectors.

Therefore, it is quite acceptable to increase this distance by up to 1.5 times if the width of the room is 3 m or less (clause 13.3.10). Any changes in the distance from the walls are not mentioned, and therefore are not allowed.

Yes, but don’t forget about reserving detectors! That is, in essence, their duplication. No, this does not quite mean that you should stupidly install a pair of sensors everywhere instead of one. In fact, this means that every point of the protected space must be monitored simultaneously by at least two sensors. The difference is small, but it is there.

What is this for? It's simple: if for some reason one detector fails, then full control will still be maintained. By the way, the launch of an automatic fire extinguishing, smoke removal or warning system is carried out only by a signal from two sensors.

The distance between duplicate detectors should be no more than half of that prescribed by the requirements in a particular room. You don’t have to bother and simply install them next to each other, but the aesthetic component of such a solution, in my opinion, is questionable.

In fact, since we still live in the 21st century, I would recommend abandoning point, non-addressable sensors, redundancy and the like. Today there is addressable detectors with performance monitoring, addressable analogue, which eliminates uncontrolled failure of the system.

Therefore, the standards do not require their duplication, and the degree of their recognition is so accurate that the activation of automatic systems and the blocking of engineering systems occur based on a signal from one sensor.

Of course, such equipment is much more expensive than point detectors. However, taking into account all the nuances described above, the final cost will be lower. And there’s nothing to say about safety.

When designing the location of fire detectors, be sure to take into account drafts, that is, convection currents, and the fact that air conditioning and ventilation can negatively affect the response of the sensors. Therefore, the distance from the detector itself to the hood or air conditioner drain must be at least 1 m.

If your ceiling resembles a honeycomb, of course, installing sensors will require special approach and attention. But Table 13.2 and Figure 2, located side by side in the same set of rules, essentially leave you no room for maneuver.

In a word, stock up on the described regulatory documentation: delve into it, understand it, our job is to help you follow the path of least resistance and deal with regulatory acts.

Fire Alarm Testing

The need for operable fire alarm systems is obvious. And to monitor it, appropriate tests must be carried out regularly. Like everything else in the field of fire safety, the fire alarm inspection itself and its frequency are regulated.

What is the test? After installation, a representative of the PB regulatory authorities will definitely come to you, who must verify the presence of the alarm system itself, the correct selection and installation of detectors and the operability of the entire system.

But you, in turn, should not make a mistake - conclude a maintenance agreement in advance, and it is reasonable to do this with the organization that carried out the design and installation. However, we will leave you some tips, because the system of fines for non-compliance with these requirements is only increasing day by day.

The fire alarm system must be checked during installation, during setup and during regular maintenance.

As a rule, the entire test is carried out according to two scenarios: a detector signal is simulated from the control panel or using magnetic keys to trigger an alarm (does not take much time, but, in fact, does not test the sensors for real functionality); Several randomly selected sensors are exposed, depending on the type, to either smoke (eg paraffin oil) or temperature (hair dryer, incandescent lamp).

Naturally, the second option, as a test, is of higher quality, but also more time-consuming - up to 10 minutes per detector. But each smoke sensor should be tested once a month, and a heat sensor - 3 times a year.

One way or another, at the end of the inspection a corresponding report on its results is drawn up.

Regarding the rest, the external visual inspection elements should be carried out once every 2 weeks, inspection and testing of power supplies, main components of the system - every month, grounding - once a year, and insulation - once every 3 years. And every 5 years the batteries of autonomous power sources must be replaced.

Well, that's all for today. I hope we managed to resolve your difficulties, but if you have or have any questions, then, firstly, most likely you will find answers in our past or future publications, and secondly, subscribe to our blog, write yours in the comments reviews and questions - nothing will be left unattended.

There has been some noticeable progress towards the harmonization of GOST R 53325 with European standards. Perhaps in the near future our market will get rid of manual call points-puzzles, and users will get rid of the need to replace or “duplicate” manual call points if they lose their keys

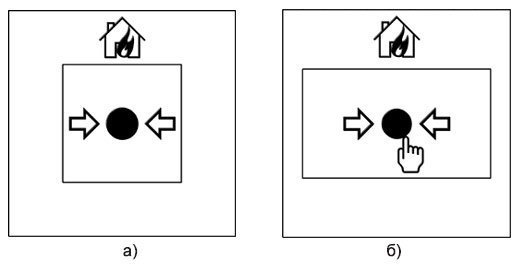

A manual fire detector (IPR), as defined by GOST R 53325-2009, is a fire detector “designed to manually activate a fire alarm signal.” The IPR is switched to the “Fire” mode by acting on the so-called drive element, which at present, according to GOST R 53325, literally anything can be used: a lever, a button, a fragile element or other device.

"Duplication" of manual call points

Probably, when developing the first IPR designs, the low reliability of contact switches, the possibility of contact oxidation, loss of spring properties, etc. were taken into account. As a result, an IPR with a lever drive element with a magnet and a reed switch began to be produced. A reed switch is a sealed switch with spring contact made of magnetic material In standby mode IPR under the influence magnetic field the reed switch contacts were closed. When the IPR was activated, the lever was moved to a horizontal position, the magnet was removed from the reed switch, and its contacts opened. Returning to the IPR standby mode is possible only with the use of a special key, which is often lost during long-term maintenance.

Rice. 1 “Duplication” of IPR

As a result, you can observe the following picture: two manual call points located in one place, one IPR in the “Fire” mode, the other in standby mode. To prevent the key to the new IPR from being lost, it was “hidden” under a protective transparent cover (Fig. 1 ).

Puzzle detectors

Obviously, the variety of methods for activating IPR only reduces the level of fire safety. On our market there are real puzzles with levers, brackets, slats in cases various forms. Quickly determine what it is intended for this device and how to handle it is not possible.

"Understandable" manual call points

The European standard EN 54-11 sets clear requirements for the shape and dimensions of the housing and drive element, as well as the shape and dimensions of symbols. This determines the absence of exotic designs among imported handbrake handles and the ease of handling them.

Rice. 2. Handbrake front panel according to EN 54 - 11

According to EN 54-11, it is only permissible to use a square housing with a face size of 85x85 to 1 35x1 35 mm and only with a flat drive element - square or rectangular. The square drive element makes up 25% of the area of the front panel, and the rectangular one makes up 32% of the area with an aspect ratio of 1:2 (Fig. 2 a, b).

Harmonization of GOST and European standards

We can note some progress towards the harmonization of our GOST R 53325 with European standards. Yes, in the project new version There are in the form of recommendations examples of IPR designs and the symbols used, their location and dimensions from the SO 7240 standard. In the requirements for the IPR design, in addition to square housings with drive elements, square and rectangular shape, there is an example of the appearance of an IPR with a round body and a round drive element.

The Eurosymbols that should be applied to the front surface of the IPR are given and it is also indicated in which place they should be applied. For example, the “House” symbol should be located above the drive element on the central axis of the front surface of the IPR. In the area where the drive element is located, the “Arrows” symbol should be applied. Defined not only appearance each character, but also their relative sizes.

In addition, with the introduction in the near future of a new version of GOST R 35525, manual call points will be classified as in European standards - into two classes depending on the number of actions required to activate the IPR. If it is enough to perform one action to transfer class A IPR to the “Fire” mode, then class B IPR is activated after performing two actions. The first impacts on a flat element are the same in terms of force in the IPR of both classes, but in the IPR of class B then another is performed, for example, by pressing a button. The IPR class B drive element is additionally marked with the “Hand” symbol (Fig. 2.6). For IPR class A, a transparent cover is allowed to protect the drive element from accidental impact. It is possible that future versions of the rulebook will define the purpose of Class A and Class B IPRs.

Installation Rules

Code of rules SP 5.13130.2009 defines the installation of manual fire call points on walls and structures at a height of (1.5 ± 0.1) m from the ground or floor level to the control (lever, button, etc.); at a distance of at least 0.75 m from other controls and objects that impede free access to the detector; at a distance of no more than 50 m from each other inside buildings and no more than 150 m from each other outside buildings.