Sawing with maximum profit! cutting logs optimization program increasing profits. Sawing round timber: cutting map, necessary tools Cutting program for band sawmill

Forest sawing is a cycle of actions using a variety of technologies aimed at obtaining lumber from round timber suitable for further use in industry. The duration and labor intensity of the process depend on the chosen method of processing round timber, as well as the time of year.

Tools and equipment

Barrels and large size branches. All material is divided into groups according to thickness and presence of bark. Often, timber processing enterprises have workshops near the harvesting site, in which machines for the initial processing of wood are installed.

Manual debarking of wood

Wood that has not passed the debarking stage can be used for flooring or as ridge beam in the appropriate interior, or as a supporting device during construction.

Industrial debarking of forests

If another option for using the wood is planned, then sawing is carried out, resulting in the following segments:

- unedged and semi-edged (rough material from which the bases of the floor, walls or ceiling are mounted);

- edged (intended for finishing flooring).

The cutting can be carried out by a mobile organization that has all the necessary tool.

Wood cutting map

Rational use of the material is ensured by compliance with the cutting map. This allows you to reduce costs due to waste, the percentage of which the card can significantly reduce. The tools and types of forest processing equipment used depend on the volume, desired quality and size of the finished lumber.

The most commonly used are a circular saw and various machines:

- circular due circular saw Allows for precise cuts various directions. Suitable for both professional and home use, copes well with above-average round timber diameters;

- chainsaw;

- machines for net withdrawal bark;

- sawing on a band sawmill makes it possible to process dense logs; it is considered the most popular, since the yield gives quality material and a small amount of waste;

- disc machine: production of double-edged timber and unedged boards;

- a frame sawmill does not require a foundation, the technology using it allows you to install the equipment in close proximity to the felling site;

- fine meter processed universal machines, the output produces high-quality building materials even from low-grade logs;

- sawing of round timber at a large woodworking enterprise should be carried out with the largest number lumber that differs from the rest in its special quality and precise dimensions. For this purpose, special lines are installed for sawing.

The sawmill produces timber and edged board thanks to cutting logs up to 7m long and 15-80cm in diameter along the longitudinal line. A circular saw has one or more disks and processes wood of different diameters according to their number.

If you need to process a small amount of wood at home, you can use a regular chainsaw.

Cutting wood

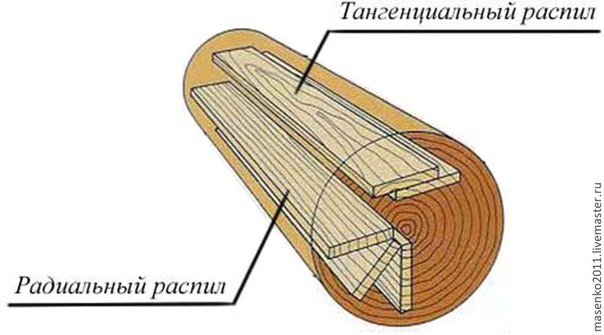

Before choosing a tool, you need to decide on the type of cut, focusing on the annual rings of the log. There are several types:

- radial (along the radius);

- tangential (the cut is parallel to one radius and touches the annual rings);

- the fibers are located parallel to the cutting being performed.

Among the cutting methods, the one that is most suitable for a particular case is selected:

- Waddle. Sawing wood in this way is done for deciduous trees with a small trunk thickness, it is considered the simplest processing. Output: unedged elements and slabs.

- If you have another forest processing machine, then it is possible to cut up to 65% of the material to produce edged boards of equal width. First, the double-edged timber and boards on the sides are cut, and then a certain amount of edged lumber is obtained from the timber.

- More specific methods are sector and segment sawing. The number of elements in the first method varies from 4 to 8, and depends on the thickness of the trunk. After dividing, elements are cut from each sector along a tangential or radial line. The second method begins with the timber coming out of the central part, and boards are cut from the side segments in a tangential direction.

- For individual cutting of wood, the circular method is suitable. It is based on turning the log along the longitudinal line by 90° after each sawn board. This allows you to monitor the quality of the wood and promptly remove affected areas of the trunk.

Manual work: using a chainsaw

For home cutting of several trunks, it is not advisable to purchase a tool whose cost is several times higher than the price finished products. If you have the necessary skill, then it is more efficient and cheaper to do the whole necessary work a regular chainsaw, or chain equipment powered by electricity. Of course, such work requires much more physical effort and time, but the cost of the issue is significantly reduced.

Working on a garden plot requires pruning fruit trees, and it is also possible to produce additional material for outbuildings without resorting to the services of specialists, so any zealous owner will prefer to buy a chainsaw. Most often, coniferous wood is harvested for the home, and this tool does an excellent job of cutting it. Thanks to straight trunks, it is easier to mark cutting lines, which increases the speed of work. Professionals, by the way, most often use a chainsaw, since it is more powerful than an electric one and can be used anywhere, regardless of whether there are power sources at the cutting or cutting site.

To use a chainsaw to cut logs, you will need a device such as a saw attachment, as well as cutting guides and base-trunk fasteners. The frame-shaped attachment is attached to the tool so that it remains possible to adjust the distance between the chain and the frame itself. This is done to make it possible to produce finished lumber of different thicknesses. For the role of a guide, you can take either a profile of the required length, or a flat wooden plank with sufficient rigidity. A special chain is selected for the tool, designed to cut the trunk lengthwise. Its difference from the others lies in the teeth sharpened at a certain angle.

Before you start work, you need to not only prepare all the necessary tools. Regardless of whether a woodworking machine or a manual device is intended for processing the trunk, the first thing you need to do is familiarize yourself with the cutting map. This is done in order to minimize the percentage of waste and increase the yield of useful products.

The first thing you need to worry about when cutting longitudinally is the uniform density of the finished boards. To do this, a competent sawyer directs the tool from the east side of the log to the west, or in the opposite direction. This is explained by the higher density of round timber in its northern part than in the southern part.

Next, use a chainsaw to remove the slab from both sides so as to obtain a double-edged beam. It, in turn, is sawed in accordance with the cutting pattern chosen at the beginning of the work. The solution is an unedged board. If there is a certain percentage of defects in the trunk, then a circular cut is possible with the trunk turning at a right angle or 180°.

Quantity of finished material, cutting price

Exit useful material from coniferous and deciduous species differs in percentage. For lumber obtained from coniferous trees, the following indicators are characteristic:

- provided that the operation is carried out by a professional and a circular sawmill is used, the percentage of finished wood will be the highest (80-85%);

- the edged material produced by the machines averages 55-70%;

- When used with a chainsaw, an unedged board leaves up to 30% waste.

The figures are given without taking into account the finished culled timber, the amount of which can reach 30%. However, such material is used for products that allow certain defects.

Deciduous round timber produces 60% of the finished unedged timber and about 40% of the edged timber. This is explained by the initial curvature of the round timber. It is possible to increase the amount of products obtained: this will require forest processing machines of various types. A certain kind of device can increase the amount of lumber by 10-20%. For one cube of lumber you will need about 10 cubes of deciduous round timber. The cost of installing additional equipment will be recouped by the cost of the finished timber. Special lines give a larger volume, but their use is advisable only for large plot. The average price of sawing wood at a regular sawmill will be approximately 150-180 rubles per cubic meter of boards.

Sawing map

The sawing map is a calculation of the optimal amount of finished lumber from one log. You can calculate it yourself for each specific log diameter, or you can use a computer program that greatly facilitates the calculation, and the price of which is quite affordable.

Or the source could be a regular sawmill reference book. The result is a table that is used as a basis. The sawmill attachment must always be oriented towards its data in order to obtain more lumber of any type of wood.

All photos from the article

In this article we will talk about how to cut logs on a band sawmill. In addition, we will consider what are the criteria for selecting one or another method of wood processing and how this affects the characteristics of the finished lumber.

Methods for cutting logs to produce various lumber have been developed and improved with for a long time, since this is the only opportunity to obtain edged boards, timber and other categories of similar products from a single tree trunk.

From ancient times to the present day, methods of wood processing have evolved, and in addition, new, more productive equipment has appeared that makes it possible to obtain the necessary lumber quickly and efficiently. minimum quantity industrial waste.

Features of wood processing

The instructions for processing raw materials and obtaining lumber products consist of a number of technological operations, including longitudinal cutting of logs, trimming lumber and cutting to width, sorting by standard sizes, sorting by quality of workmanship, drying and storage.

Each of the listed stages is important from a quality point of view finished products. But cutting is the most labor-intensive and critical stage, during which the main characteristics of the finished lumber are formed.

Drawing up a plan for cutting logs into lumber (choice suitable method processing) depends on the type of wood, the size of the raw material, the degree of humidity, the density and hardness and many other factors. Of course, the method of processing raw materials is determined to a large extent based on the level of technical equipment of the enterprise.

Let's consider what equipment is used for industrial sawing of wood and what methods are relevant for each category of this equipment.

Cutting equipment and features of its use

The following categories of equipment are used for longitudinal cutting of logs:

- Single band saws or circular saws are a traditional solution that has been used for a long time.

- Group frame saws- a more progressive solution that can significantly increase the productivity of raw materials processing without compromising the quality of the finished product.

Let us consider in more detail the features of the application of the listed categories of equipment.

- Individual cutting is a method that uses single saws. In this case, only one cut can be obtained in one saw pass. Therefore, the entire tree trunk can be cut in several passes.

Important: The advantage of individual cutting is the independence of each subsequent cut from the previous one.

That is, sawing can be carried out in different planes.

As a result, it becomes possible to use certain properties more rationally different parts logs

At the same time, this method is low-productivity and therefore not suitable for use in large woodworking enterprises.

- Group sawing- This process, during which a group of frame saws is used.

The advantage of this method is that the log is completely cut in one pass. This saves time and, as a result, reduces the cost of production. But you need to remember that group sawing is performed in one plane.

Today, the following categories of equipment for group sawing are most widespread:

- narrow-clearance vertical frames, machines with circular saws, milling saws (diameter of processed raw materials from 14 to 22 cm).

- medium-clearance vertical frames (diameter from 24 to 48 cm)

- wide-clearance vertical frames, double and quadruple bandsaw-type units (diameter of processed raw materials over 50 cm).

New visitor

Registered visitor

Detailed description functions of log cutting programs. We offer you an assistant who will increase the wood yield by 10-15%, and speed up the process of preparing cutting sheets by 500-700%.

Pi2 program for cutting logs into boards of the same specified width and thickness.

Running Pi2 gives the following result:1. Technological maps cutting logs.

2. Increased sawing productivity by 10-15%.

3. Reducing the dependence of productivity and cutting quality on the human factor.

“Reverse” calculations are possible: the user specifies only the dimensions of the board, and the program suggests (calculates) the minimum size of the log that is needed to produce this board. You can sort the logs based on the size of the boards.

To choose the best cutting (highest yield), perform many calculations. The calculation report is presented in Excel. It is convenient to import data into your accounting system.

Pitago (Pitago) - a smart assistant engineer...

Wane point* is the distance in meters from the thick end of the log, starting from which wane appears in the direction of the thin end due to the convergence of the logs.

Pitago - completely online solution, you can use it on any device including mobile phones and tablets.

When sawing wood, it is important to immediately calculate what the consumption will be, as this will affect the cost of lumber. The yield of finished products may vary. It all depends on the quality of the wood used and whether measures are taken to optimize cutting. There are special measures to increase work efficiency, make the output better, and the quality of sawing higher. Before sawing, you need to pre-calculate everything. This is not as difficult as it might seem, but the consumption of round timber will be optimal and profitable to obtain an excellent result.

How to increase cutting efficiency

In order for the yield of lumber to be significant, it is necessary to use special measures to increase the efficiency of the process:

- The calculation should only be carried out when using special programs, manually it will have low efficiency, the percentage of defects will be high.

- The round timber must first be sorted so that processing is carried out correctly.

- For cutting it is necessary to use high quality equipment. Otherwise, the amount of waste will be large, and the quality of the resulting lumber will be low.

- It is best to cut wide lumber first; narrow lumber takes longer to process.

- It is not recommended to take long logs.

- Before work, you should set up the equipment.

The yield of finished lumber may vary. It must be remembered that at the first stage boards are obtained, then they are sorted. As a result, the percentage decreases even more; for example, for deciduous trees it can be only 10-20%.

How to optimize cutting

To increase the yield of lumber, the cutting process must be optimized. This applies primarily to those workpieces that have significant curvature. To cut a crooked round timber, you need to perform a number of steps:

- First, only suitable wood is selected for work. If the remaining logs have rot, sprouts, or cracks at the ends, then it is necessary to trim off some areas.

- If a rotten core is discovered during work, you can carefully remove it, and then saw the remaining part. This will allow you to avoid large losses and obtain boards with a length of 1 m or more with the required quality.

- It is recommended to use logs with a larger diameter so that the yield percentage is higher. The coefficient can be 1.48-2.1, but it all depends on the diameter, quality of the round timber, sorting, and equipment. For frame shops this coefficient will be 1.48-1.6, and for lines with milling equipment— 1.6 for large forest. With a round log diameter of 12 cm or more, the coefficient can exceed 2.1.

Volume of waste after sawing

In order for the finished board to come out with a high percentage, everything must be prepared correctly, the work must be carried out only in accordance with the technology. Roundwood of coniferous and deciduous species produces different yields. In the latter case, the volume is smaller, even if you use a special additional equipment. Needles are considered more convenient for sawing, since their trunk is straight and the log has a larger diameter. Coniferous forest is not so susceptible to rotting, so there is less waste. For hardwood, 2 cutting technologies are usually used:

- with the help band sawmill on Z75, Z63;

- into collapse, when a half-beam is cut out in the core of the material and passed through a multi-saw machine.

The volume of a band sawmill is 40-50%. When using technology for collapse, the yield is different, it can be increased up to 70%, but the costs of such work are higher. If you cut round timber, the length of which is 3 m, you can see that the percentage of scrap is quite large, and the remaining material requires processing. This applies to the bulk with boards 22x105(110, 115)x3000 mm. There are many options for such a marriage. For example, it could be a wormhole, which is no longer suitable for most jobs.

After sorting, the volume of hardwood material, which belongs to grade 0-2, will be only 20-30% of the amount obtained after sawing. This means that of the total mass of harvested round timber, the yield of normal boards will be only 10-20%. The remaining materials are mainly used for firewood. For coniferous round timber, the yield will be different, but attention must be paid to what average values of the resulting volume are observed.

Lumber output

In order for the yield of lumber to be optimal, numerous conditions must be taken into account. To calculate correctly, you can consider the example of round timber yield. The data was obtained from the real experience of specialists and from the performance of sawmills. This makes it possible to compare percentage, calculate optimal average numbers.

For coniferous species, the following solution is possible:

- For unedged boards and other unedged materials during sawing, the yield will be 70%. This is the amount of material obtained during processing, the amount of waste will be equal to 30%.

- For edged material, when using sawmills of 63, 65, 75, there will be a lower yield of lumber, only around 45%. For band sawmills, the yield is usually up to 55-60% finished material. If you use means to increase efficiency, you can reach 70%, although this requires extensive experience.

- From a circular sawmill you can get lumber in the amount of 70-75%, although using methods to increase efficiency it may well be 80-75%. But work experience is required.

According to GOST 8486-86, for grade 0-3, the yield percentage, not taking into account sorting, is approximately 70%.

Another 30% can be left for rejecting the finished material. Rejected material is not thrown away; it is used for the manufacture of other types of lumber, which allow for the presence of certain defects.

For deciduous roundwood, a different yield percentage is observed:

- For unedged material – 60%.

- For edged wood - up to 35-40%, since the curvature of the original deciduous wood is usually large.

The output can be increased; additional equipment is used for this. This could be a special multi-sawing machine, an edge trimming machine, or a slab machine. In this case, the yield of lumber will increase by about 20%. The given percentage is given based on data on obtaining boards of grade 0-4. When sorting grades 0-1, the percentage of lumber obtained is 10%. To get a cube of finished edged material from hardwood, you need to cut 10 cubes of the original round wood.

The yield of lumber from roundwood may vary. It all depends on the original type of wood used by the sawmill. Special measures to increase efficiency allow you to get a larger percentage than is possible, but for this you must have some experience.